Manual Soldering

LEAD FREE SOLDERING UNITS

In the following slides you will find all the new Etneo products related to welding for electronics, microelectronics and more. The innovations introduced, in almost all systems, are functions made for the purpose of energy savings and longer life of the spare-parts.

- STAND BY TIME

- AUTO SLEEPING MODE

- HIGH POWER FAN WITH BRUSHLESS MOTOR FOR HIGH AIR FLOW

- AUTO FEEDING FOR SOLDERING STATIONS

- ALL RoHS products and ESD safe design

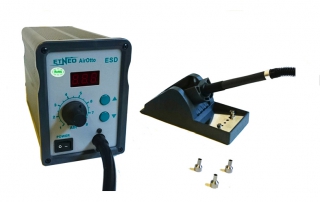

AUTO FEEDING SOLDERING UNIT

High frequency heating, rapid heating and quick thermal recovery for lead free soldering. Many different tips are available with easy replacing. Micro computer control. Temperature calibrates digitally. Temperature set by keys. Auto sleeping available. Auto and manual ways of solder feeding optional, auto solder feeding mode can, at most, solder nine successive soldering points. Imported motor, automatic feeding, sliding switch design. More functions available and adjustable, such as feeding speed, feeding volume, interval time, backing time etc. Two types of feeding hose optional, easy to use. Long hose suitable for active soldering. Short hose suitable for fixed soldering. It can be used as a lead free soldering station only. Pedal switch or manual switch available.

Through hole Desoldering

THT DESOLDERING UNITS

ESD Safe design. Powerful built-in vacuum pump. Sensor closed-loop temperature control for heating system, precise temperature. Heater, which is 36V powered, is fully isolated from mains, Safe and reliable. LED digital display; auto sleeping available as optional. Temperature calibrates digitally. Suction nozzles and heater are specially designed; high efficiency without frequent maintenance. Long lifetime Heater. Heat resistant vacuum hose used. Sleeping mode system for longer life of spare parts.

Hot Air Rework

HOT AIR UNITS

All Etneo technologies in a single station, able to reduce space on the counter and equipped with all the tools always ready to use. Takes a few seconds to remove most of the components smd-smt-pth . Ability to set up 3 profiles of re-adjusting work time-temperature and airflow. Welding tool with Ultra 90W . Desoldering gun-tool suitable container alloy . Efficiency and high speed soldering. The profile includes six phases that can change the parameters of re-work. Sleeping system for saving energy. Available optional foot pedal switch . Ability to set a time for the air flow from 1 to 999 seconds, if set to 999sec. the flow is continuous. Large LCD display for optimal viewing of temperature, working time and air flow.

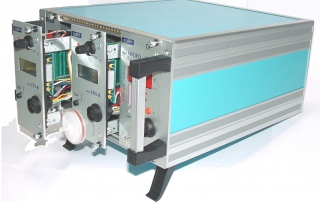

PRE HEATING UNITS

Pin point hot air system to heat the target only without affecting the component nearby. Mainly used in robotic soldering system to reduce the cycle time for solder. With a 19″ Rack standard construction for heavy duty applications. Each module is easy interchangeable and features its own power supply for the highest performances.